The last thing you want to do is drive to work sweating like crazy because the air conditioning in your car decides to take a hike. You can minimize the risk of this happening by having the system checked by a certified air conditioning tech every spring and having the heating system checked every fall. The certified technicians at Yocum Automotive provide auto air conditioning repair and maintenance so you don’t have to use the old-fashioned air conditioning – open windows.

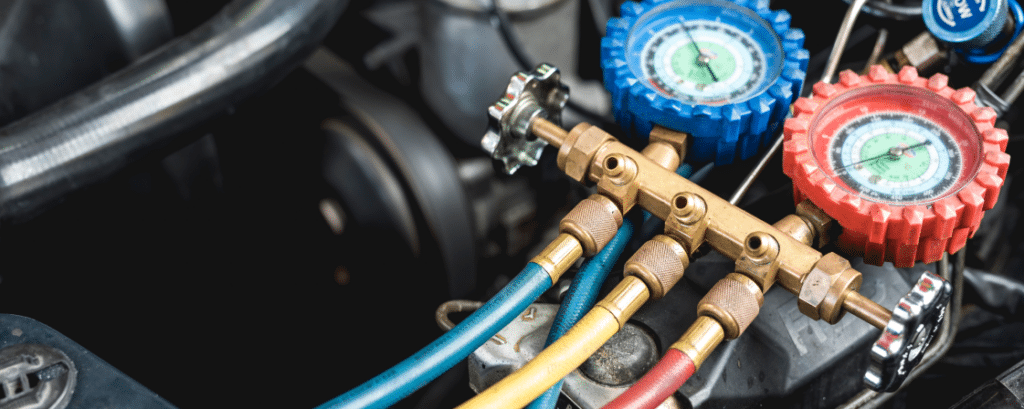

An important component of Auto Air Conditioning Repair is the refrigerant which goes into the compressor as a low-pressure gas, comes out as a high-pressure gas, goes through the condenser, which turns it into a high-pressure liquid, into the drier, then the expansion valve or orifice tube, then through the evaporator, where it turns into a low-pressure gas as it pulls heat from the vehicle’s cabin.

The air conditioning system in your vehicle contains several parts, all of which can go bad, including:

Replacing filters, checking the air conditioning system each spring, and ensuring the system does not have refrigerant leaks all help reduce the risk of failure. Of course, in auto air conditioning repair and maintenance we can’t tell when a compressor is going to fail suddenly, or an expansion block or orifice tube might become clogged, but checking the system can minimize the risk of unexpected auto air conditioning repair. If we find issues, you can schedule your vehicle for repair before the system fully malfunctions.

visibility_offDisable flashes

titleMark headings

settingsBackground Color

zoom_outZoom out

zoom_inZoom in

remove_circle_outlineDecrease font

add_circle_outlineIncrease font

spellcheckReadable font

brightness_highBright contrast

brightness_lowDark contrast

format_underlinedUnderline links

font_downloadMark links